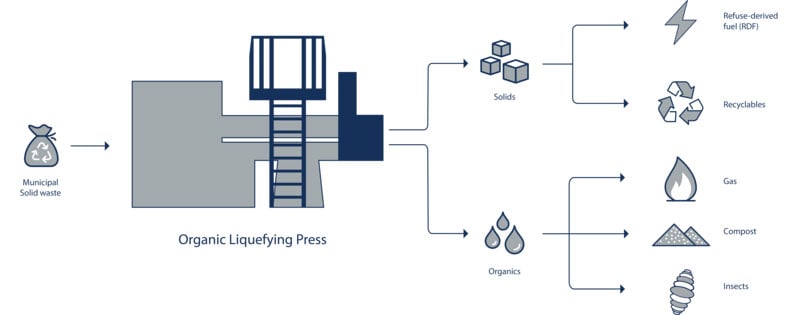

The organic fraction in mixed waste streams is ideal for producing biogas. However, despite the effort put into separating and recycling waste, many organics still end up at landfills or waste incineration plants. This way, valuable materials are lost and, moreover, cause damage to the environment. By separating or dewatering solid and fibrous waste from organics and moisture, each material can be reused to its full potential.

Overview of content

Separate the Organic Fraction of Municipal Solid Waste (OFMSW)

Separate green waste into fibers and wet organics

Separate food from packaging

Dewater paper pulp rejects

Statistics: the OLP in numbers

Separate the Organic Fraction of Municipal Solid Waste (OFMSW)

Municipal waste is one of the largest waste streams often incinerated for alternative energy or landfilled. But what waste do we classify as Municipal Solid Waste (MSW)? Well, almost all waste people like you produce every day. Add the waste of restaurants, stores, farms, manufacturers, public facilities, and there you go. MSW, therefore, consists of the everyday items we – as a society - use and throw away.

Also read: What is the Organic Fraction of Municipal Solid Waste (OFMSW)?

Incineration or landfill: double trouble

In general, 30 to 70% of all municipal waste consists of organics. That is half of all household waste on average. These organics in MSW are very suitable for producing biogas. Such a shame that these valuable materials get lost when landfilled or incinerated. On top of that, the decomposing of organic materials releases methane emissions that are up to 28 times more polluting than carbon dioxide.

Municipal waste

Municipal waste

In the case of incineration, the caloric value of the solid fractions lowers due to the presence of organics and moisture. A moisture level above 30% turns the energetic balance to become negative. Additional drying or energy is then required to reach the correct temperatures. Inefficient and non-sustainable.

The alternative

By separating the organic fraction from the mixed household waste, it can be further converted into biogas for electricity, heat, vehicle fuel, and renewable natural gas. Moreover, the extraction of solid waste fractions equals less volume, therefore freeing up space for organic material and increasing the digester’s throughput. The digestate can, in turn, be converted into organic fertilizer, animal bedding, crop irrigation, etc.

The dry fraction consists of mixed (fibrous) waste, plastics, metals, and other solids. The plastics and metals can be sorted and further recycled. The remaining waste will end up in incinerators or landfills. In the case of incineration, the extraction of organics benefits the caloric value of the waste and will, therefore, be more beneficial. Furthermore, the extraction of the organics from the solid mixed waste reduces the volume of the latter and, therefore, their weight. This yields significant savings on transportation and landfill costs.

Increase your biogas potential by up to 30%

The Royal Dutch Kusters Engineering Organic Liquefying Press extracts up to 80 to 95% of all organic material in MSW (depending on composition and equipment settings). Moreover, the cylinder press is strong enough to crack the cell walls of the organic material. As a result, the press speeds up the digestion process and increases the biogas potential by up to 30%. Besides, the press allows you to use any digester brand of your choice.

Separate green waste into fibers and wet organics

Green waste streams are formed of wet organics, moisture, dry fibrous organics (such as branches and leaves), and contaminations such as plastics. Although green waste is generally collected separately, it contains both fibrous and wet organics.

Why compost organic fibers

As with the MSW, the wet organics in green waste are perfect for anaerobic digestion to make energy. The dry fibrous organics, on the other hand, are ideal for composting. Any contamination of the waste stream, such as plastics, can be sorted out to be further recycled or transported to landfills. The choice of which will largely depend on local circumstances and the type and quality of the material.

The wet organic and dry fibrous output fractions of green waste

Composting stimulates the production of beneficial bacteria that break down the (dry) organic matter to create compost. Compost is rich in nutrients that can feed the soil of lawns, vegetable gardens, potted plants, etc. Additionally, it reduces the need for chemical fertilizer.

50/50 separation

Extensive testing at a green waste facility has shown that the Organic Liquefying Press can reach at least a 50/50 separation, depending on the composition of the input material and the equipment settings. This means 50% of the wet organics can be treated for biogas, whereas the other 50% retains the moisture content needed for composting.

Separate food from packaging

Unfortunately, around 30-50% of all food produced for human consumption ends up as waste. Worse still, most of it ends up at landfills. The main problem with food waste is that they are often leftovers that contain a mix of food (a.k.a. organics) and packaging. This contamination makes it more difficult to reuse both resources. Separating techniques can solve this problem.

Existing de-packaging equipment is capable of separating the majority of organics. However, our studies have proven that the de-packaged plastics often still contain more than half of organics by weight, which is lost when sent to landfill or incineration plants.

The organic output fraction of separating food waste from packaging

The organic output fraction of separating food waste from packaging

Establish a 40-50% weight reduction

By separating plastic packaging from organic food waste, the Organic Liquefying Press can establish a 40-50% weight reduction. The organic fraction can then be further processed by a digester. The packaging – often plastics – can be recycled, incinerated, or sent to landfill. As mentioned before, the extraction of organics benefits the caloric value of the waste in the case of incineration. Otherwise, the reduction of weight will save transportation and landfill costs tremendously.

Dewater paper pulp rejects

In the paper industry, the waste stream originated from the recycling process of paper contains paper pulp rejects that include materials such as plastics and fibers. On average, these rejects contain 70% moisture. Moisture that usually gets landfilled or incinerated.

Optimise the value of dry plastics

The large presence of water reduces the caloric value of the rejects. By dewatering the rejects, this value increases. However, the initial dewatering stage by existing dewatering solutions does not reach these levels. Additional steps are required that cost additional time, money, and energy. Moreover, transportation costs could be reduced even more by the removal of more weight by one single step.

Dewatered plastic paper pulp rejects with the OLP

Dewatered plastic paper pulp rejects with the OLP

Also read: Optimise the dewatering of paper pulp rejects

Better drying results than screw presses

Commonly used dewatering technologies, such as screw presses, generally show moderate drying results. Often, 40 to 60% of the moisture remains after pressing. The Royal Dutch Kusters Engineering Organic Liquefying Press can reach a 25 to 80% weight reduction in moisture (depending on the composition of material and equipment settings).

Statistics: the OLP in numbers

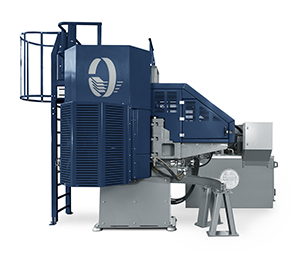

The Royal Dutch Kusters Engineering Organic Liquefying Press

The Royal Dutch Kusters Engineering Organic Liquefying Press

Depending on the composition of the material, equipment settings, and initial moisture levels, the Royal Dutch Kusters Engineering Organic Liquefying Press can reach the following levels of separation:

- 80-95% extraction of all organic material in MSW

- 50/50 separation in wet and fibrous organic fraction for green waste

- 40-50% weight reduction for de-packaging plastics from food waste

- 25-80% weight reduction by dewatering paper pulp rejects and plastics

For more information on the applications of the Organic Liquefying Press and the equipment itself, please download our free brochure.