High-quality insect larvae separation

In recent years, the growing market for insect farming has inspired us to use our years of experience in separation technology to deliver a high-standard solution for the insect industry.

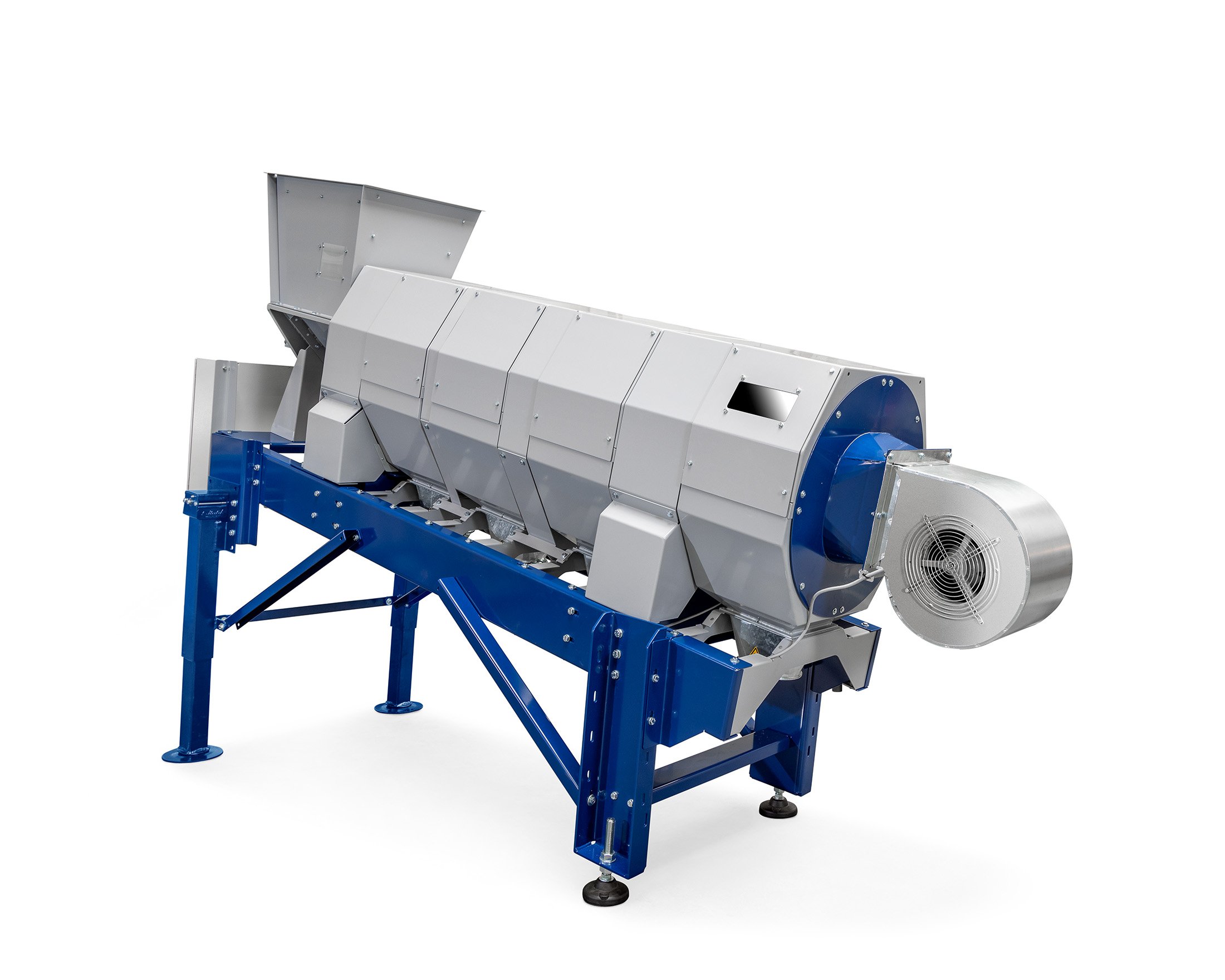

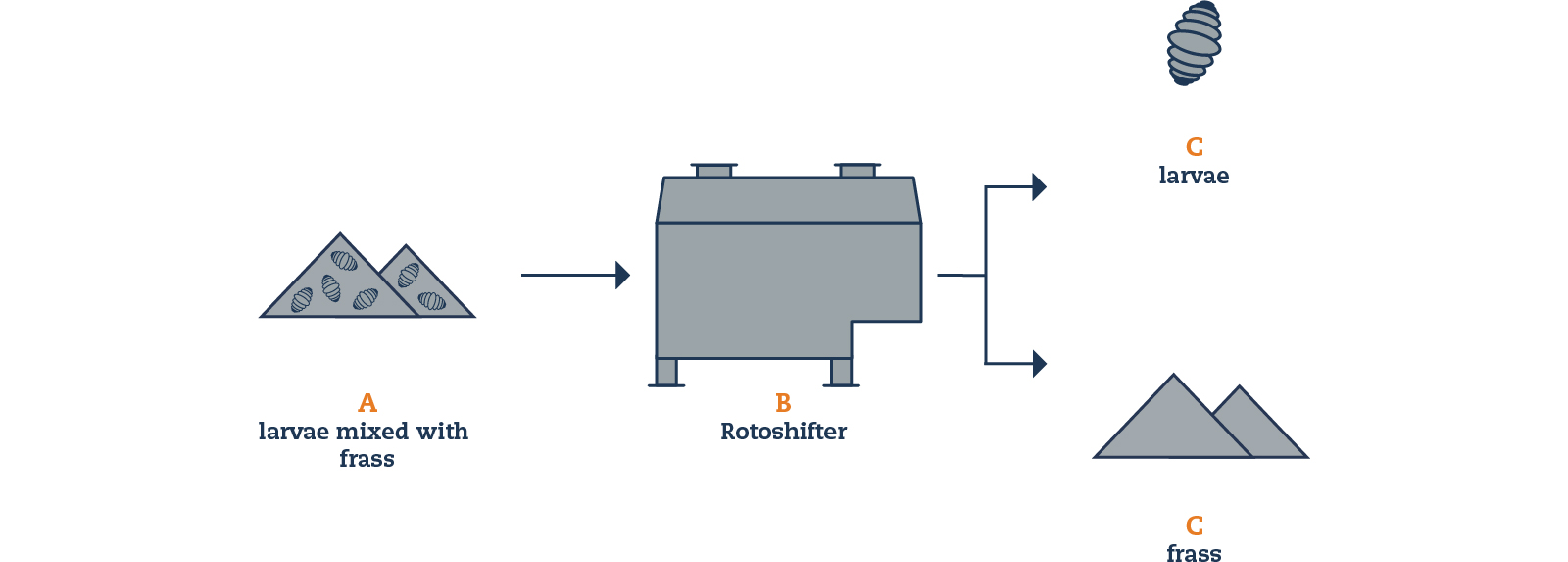

The Rotoshifter is an example of our commitment to advancing insect rearing practices. When the insect larvae have reached the desired stage, they need to be separated from the remains of the food and insect manure, the so-called frass. The Rotoshifter efficiently separates insect larvae from frass, ensuring minimal loss and maximum purity.

With the Rotoshifter, we're setting new standards for sustainable insect rearing worldwide. We can support businesses rear insects more efficiently while minimizing waste and environmental impact.

Download leaflet

Download leaflet