Sorting Compost

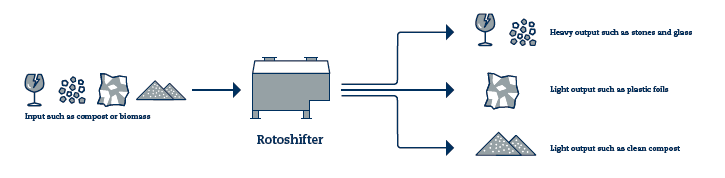

Optimise the sorting of compost by separating materials such as glass, stones and plastic foils from the material.

Energy-efficient compost sorting in two stages

Even with proper kitchen and garden waste collection, impurities in compost are never completely avoided. The Rotoshifter combines two separating techniques to achieve pure compost in an energy efficient way: wind shifting and drum screening. This results in a two stage separation process. In the first stage, air separation is used for complete separation of various light materials. Secondly, screen separation provides separation based on size.

Contact an expert

Contact an expert