Banknotes, we all know how they look and how to use them. Most of them are made from paper, but more and more countries are adopting polymer banknotes. In this blog, we will take a closer look at how polymer banknotes are made and what their pros and cons are.

Overview of content

What are polymer banknotes made from?

How are polymer banknotes made?

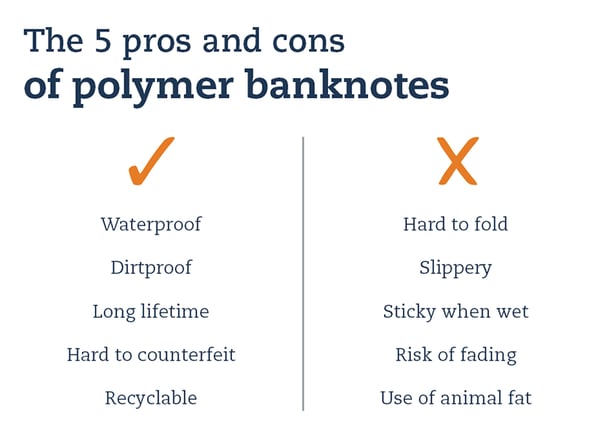

What are the advantages of polymer banknotes?

What are the disadvantages of polymer banknotes?

What happens to damaged, unfit polymer banknotes?

What are polymer banknotes made from?

Polymer banknotes are made from synthetic polymer substrates (polypropylene) that consist of chains of joined individual molecules or monomers.

The reason to use polymer is that it is strong, printable and suitable for enhanced security features. Furthermore, the surface of the polymer banknotes is very smooth. That is why these banknotes are less susceptible to dirt.

How are polymer banknotes made?

The process starts with polymer pallets. These are heated and blown into a big bubble of liquid polymer. By putting pressure on the bubble and cooling it down, a unique laminated polymer film is formed used exclusively for banknotes. The film is then rolled up into large wheels. The next step is treating the film with special inks to make it opaque, except for the areas where the clear windows will appear.

The film is now cut into sheets and ready to be printed. First, the background is printed onto both sides of the sheets. Then the security features are added followed by the portraits, narrative elements and serial numbers. Finally, the banknotes are covered by a protective overcoating ink and cut into the size of banknotes we know.

What are the advantages of polymer banknotes?

- 1. Waterproof

- Polymer is resistant to water. The banknotes will, therefore, suffer little from high humidity or rain.

- 2. Dirtproof

- As mentioned, the surface of polymer banknotes is very smooth. The banknotes are thus less susceptible to dirt. Moreover, if the banknotes do get dirty, it is relatively easy to clean them.

- 3. Long lifetime

- Besides being water and dirt resistant, polymer banknotes can also withstand extreme temperatures. They suffer relatively little from local circumstances.

- 4. Hard to counterfeit

- Partly by the three-dimensional structure of the polymer, polymer banknotes can be provided with high tech security features. It requires a specific and expensive, yet effective technology that has proven to reduce the numbers of counterfeiting remarkably.

- 5. Recyclable

Polymer banknotes are recyclable. All that is needed is to palletize the shredded polymer notes at high temperatures. The recycled polymer pallets can then be turned into new plastic items, like compost bins, flowerpots and power sockets.

Also read: From banknote to power socket; Processing polymer banknotes

What are the disadvantages of polymer banknotes?

- 1. Hard to fold

- Polymer banknotes are relatively hard to fold. There will be a crease along the fold line when force-folded.

- 2. Slippery

- As mentioned twice, the surface of polymer banknotes is very smooth. Being smooth has advantages, but can also be a disadvantage. It makes the banknote relatively slippery and so less comfortable to hold, count and transfer.

- 3. Sticky when wet

- Polymer banknotes can get sticky when wet. That is also why the banknotes are relatively less comfortable to hold, count and transfer. Furthermore, the latter two points can be a problem for sorting machines at Central Banks.

- 4. Risk of fading

- There is a risk that the colors of polymer banknotes fade. It happened in Nigeria and is possibly a climate-related disadvantage.

- 5. Use of animal fat

- In polymer banknotes, animal fat is used. The use of animal fat has caused a stir in the United Kingdom. Vegan and religious groups are not happy with this. However, the alternative - switching to palm oil - has been rejected by the Bank of England. The production of palm oil is known for being non environmentally friendly.

Also read: The 5 pros and cons of cotton banknotes

What happens to damaged, unfit polymer banknotes?

Each banknote returns for a check-up to the Bank or Cash Centre every once in a while. The exact period (weeks, months) differs per country and denomination. When the banknote is ripped or damaged, it is labelled as unfit and will be destroyed by being shredded into small pieces. Unable to be restored.

Also read: Destroying polymer banknotes is not so difficult

These shreds can then be recycled. By heating the polymer shreds, the polymer substrates and inks mix. Through cooling it down, recycled polymer pallets are made. They form the foundation for all kinds of polymer products. The polymer banknotes will not be reprocessed into new banknotes because the mix of polymer and inks in the recycled polymer does not meet the high standards.

However, more and more countries have both cotton and polymer banknotes in circulation (or a mixed substrate called hybrid banknotes). Either because:- they chose to issue only certain denominations on polymer (often the denominations that are most used and have a short lifetime);

- they just started issuing polymer banknotes, and not all values have been designed and approved yet;

- during the switch to polymer, the cotton banknotes remain legal tender for a transition period.

To be able to recycle the cotton and polymer shreds simultaneously, an upgrade of the banknote destruction process – like our project at the Bank of England - is needed.

Discover our currency destruction solutions

Royal Dutch Kusters Engineering is the world's leading manufacturer of currency destruction equipment. We design, develop, deliver, install and service reliable and secure destruction solutions for all types of banknotes.

If you want to know more about our banknote destruction solutions, please download our banknote destruction brochure.

Keep informed on the latest insights and subscribe to our blog.

Sources

Carnegie Mellon University

Reserve Bank of Australia

Bank of England

Banknote World