Although the concept of banknote destruction is the same for all substrates, we are happy to explain the whole process for polymer notes in this blog.

Overview of content

Stage 1: Two-stage shredding

Stage 2: Static-free shred extraction

Stage 3: Cost-efficient shred collection

What happens with the polymer shreds after they are collected?

Stage 1: Two-stage shredding

Since the beginning, Kusters has used two-stage destruction in its Currency Destruction System (CDS) machines. This technology has been invented in 1979 and has been a patented solution for many years. Why have we always used this construction? Well, for a destruction shred size of under 30mm2, it is highly recommended to use a two-stage set-up to guarantee absolute secure destruction.

Before the banknotes are destructed, the system has to be loaded and locked securely. A belt will then transport the banknotes towards the first shredding stage, the pre-crusher. Royal Dutch Kusters Engineering has always used anti-static belts in these systems. Otherwise, static electricity could arise during transportation, causing the banknotes to stick and jam the system. For polymer banknotes, this is even more relevant.

Royal Dutch Kusters Engineering CDS V-Series

Royal Dutch Kusters Engineering CDS V-Series

The pre-crusher does nothing more than cutting the banknotes into stripes. An air extraction fan takes care of transporting them to the second stage, the granulator.

The granulator then cuts the shreds until they are too small to be restored to banknotes. In general, the most accepted shred size is 6x6mm. However, the shred size output of all our CDS machines can be adapted to the customers’ requirements, larger but also smaller.

Also read: Shredding and Granulating; Sustainably Destroying Unfit Banknotes

The most important factor for reliable polymer banknote destruction is the tuning between the pre-crusher and the granulator in combination with the extraction set-up (stage 2). This is because the knife schedule has to be heat dissipating to prevent the polymer shreds from melting and thus disrupting the operation.

That is also why our granulator knives are one piece. A one-piece absorbs and extracts heat better and faster. In this way, the knives ensure good heat transfer and easy cooling of air. Extra measures - such as temperature sensors - are, therefore, redundant. Royal Dutch Kusters Engineering has been using this set-up for many years already for both cotton and polymer destruction systems.

![]()

Did you know... the standard knives used in the Kusters Banknote Destruction Systems are even better suited to shred polymer than cotton or hybrid banknotes.

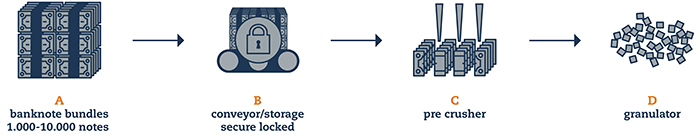

In the flowchart below, you see the process of operation of our CDS machines. They can handle an input of 1.000 to 10.000 banknotes at once (A) that will be loaded onto the conveyor (B), and then the system will be securely locked by the operators and/or security officers. Now, the operators can safely leave the room, our load-lock-leave principle. The anti-static belt will transport the banknotes towards the pre-crusher (C). The second – and final – stage of destruction is the granulator (D) to ensure the right size of shreds.

Stage 2: Static-free shred extraction

After the shreds have reached the desired size, they go through the sieve and are transported by the transport fan into the collection system (stage 3) of choice. A single air transport fan is responsible for the shred extraction from the pre-crusher to the granulator and from the granulator to the collection units.

When dealing with polymer notes, the main element of shred extraction is neutralizing the static charge that may occur due to the natural composition of the polymer. This neutralization of static charge is essential because, otherwise, the polymer shreds get stuck in the system, causing security and operation issues. Fortunately, the placement of ionisation units in critical places in the system(s) can easily remedy this issue.

Also read: Extracting, collecting and compacting the shreds of unfit

Polymer-based banknotes of Costa Rica, Scotland, Maldives and Brunei

Polymer-based banknotes of Costa Rica, Scotland, Maldives and Brunei

Stage 3: Cost-efficient shred collection

Finally, the shreds are collected in the collection unit of choice. We recommend gathering the banknote shreds into a collection system with an integrated self-cleaning air filter because of the dust involved, especially with the destruction of polymer banknotes.

Our Shred Collection Unit (SCU) comes in various versions and works as follows. The transport fan blows the shreds into the unit, where the anti-static filter bags separate the dust from the shreds. A screw conveyor then distributes the shreds to the connected sacks, big bags or other collection options of choice. In this way, replacing the sacks, big-bags, etc., is a clean operation and safe for the operating staff.

Royal Dutch Kusters Engineering SCU-100

Royal Dutch Kusters Engineering SCU-100

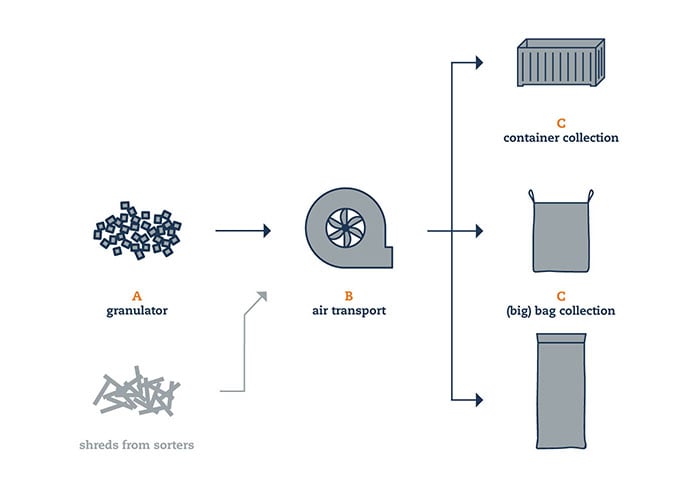

In the flowchart below, you see how the shreds are extracted from the granulator (A) by the transport fan (B) towards the shred collection unit of choice (C). Our solutions can also handle shreds from online destruction solutions (shreds from sorters, for instance). Even more so, Royal Dutch Kusters Engineering has successfully connected hundreds of these online destruction systems – irrespective of the brand – to our shreds handling solutions worldwide.

The entire process flowchart from the two-stage destruction to the collection of unfit banknotes can be found in our banknote destruction brochure.

What happens with the polymer shreds after they are collected?

Some would consider recycling the final step in the process of destroyed polymer banknotes. For a reason, one of the main advantages of switching to polymer-based banknotes is its recyclability.

However, as a condition for recycling the polymer shreds, they should be collected (stage 3) with caution. More specifically, they should never get mixed up with other substrates. That is because when shreds of various substrates are extracted to the same collection unit, the polymer shreds could get contaminated by other substrates, eliminating the possibility for high-quality recycling and thus its value and circularity.

When optimising your banknote destruction system to polymer, the separate collection should, therefore, be a priority.

To recycle the polymer banknote shreds, they can be heated and palletized at high temperatures. Subsequently, the pellets can be put in moulding to make low quality recycled plastic items. The pellets, however, will not be used in new banknotes because it consists of a mix of polymer and inks that do not meet the high standards set for polymer banknotes.

Whether the polymer shreds will indeed be recycled depends on the local circumstances. Royal Dutch Kusters Engineering is, therefore, engaging in opportunities to recycle polymer shreds. One of the additional benefits for (central) banks and printing works would be the lower - or even elimination - of costs for the disposal of banknote destruction waste, as this former waste would then be a raw material for new, high-quality products.

Would you like to stay up to date and support the further development of these initiatives? Subscribe to our polymer recycling updates:

Discover our currency destruction solutions

Royal Dutch Kusters Engineering is the world's leading manufacturer of currency destruction equipment. We design, develop, deliver, install and service reliable and secure destruction solutions for all types of banknotes.

If you want to know more about our banknote destruction solutions, please download our banknote destruction brochure.

Keep informed on the latest insights and subscribe to our blog.