When government agencies are in the market for equipment to securely shred documents, they rely on various guidelines to determine if the shred size aligns with their desired level of security. These guidelines are primarily based on the DIN (Deutsche Industrial Norm), a term coined by German manufacturers of the popular office cross-cut shredder. These shredders are specifically designed for handling smaller volumes of documents. The DIN guideline specifies the maximum shred size recommended for different levels of secure destruction across a wide range of data materials. In this article, we delve into the world of cross-cut shredding, granulation, the DIN guideline for paper (P), and explore why the current method of connecting security level and shred size may not be the most optimal approach.

Cross cut shredding and Granulation

Generally when asked to imagine shredding, the picture we have in mind is one of a cross cut shredder. However, it is not the only method used for the destruction of secure documents. Another common technique is by means of a granulator, which is more often used for the bulk destruction of larger volumes of documents and larger packages such as boxes and containers.

What is a granulator?

A granulator is a powerful and innovative machine that revolutionizes the process of secure document destruction. With its high-speed rotating knife mill, featuring stator and roto knives, the granulator is able to effectively obliterate even the most sensitive documents, ensuring complete destruction and minimizing the risk of information leakage.

Unlike traditional shredders, which operate at slower speeds, granulators are designed to work at high speeds, allowing for efficient and fast document destruction. In fact, granulators are often integrated into multistage shredding systems that are equipped with pre-crushers or industrial shredders. This integration enhances the overall shredding process, making it more seamless and efficient.

One of the key features of a granulator is its ability to regulate the size of the shredded particles. This is achieved through the use of a screen, which ensures that the particles are cut to the desired size. The granulator continually cuts the particles until they are small enough to pass through the screen, guaranteeing thorough destruction and eliminating any chance of reconstruction.

The combination of high-speed operation and customizable particle size regulation sets the granulator apart from traditional shredders. It offers a level of precision and efficiency that is unmatched in the industry. By utilizing a granulator, government agencies and organizations can have complete confidence in the secure destruction of their documents.

In summary, a granulator is a cutting-edge machine that revolutionizes the process of secure document destruction. With its high-speed operation, integration into multistage shredding systems, and customizable particle size regulation, the granulator ensures thorough and effective destruction of sensitive information. By incorporating this advanced technology into their document destruction processes, government agencies can maintain the highest level of security and minimize the risk of information leakage.

Capacity

Although cross cut shredders are ideal for smaller volumes of documents, granulators have a distinct advantage when it comes to larger volumes. As mentioned previously, the ability to repeatedly cut particles enables granulators to efficiently handle large amounts of paper all at once.

The difference in shreds

One notable distinction between the two methods is that while a cross-cut shredder has a set shred size, a granulator has the ability to generate partial outputs of shreds that are actually much smaller than what is needed through the repeated cutting process. However, the granulator's shred size may not be as consistent.

Maximum individual shred size as a secure shredding label

When examining the DIN regulations, particularly DIN 66399, we analyze the maximum surface area and width of shredded particles, which are then classified into various security levels. A crucial aspect of this evaluation is that each individual shred particle must be smaller than the specified measurement. If 99% of particles meet the size recommendations but 1% exceeds it, the shreds are not deemed suitable for that particular security level. However, this regulation fails to consider whether this approach truly provides the safest means to prevent document restoration.

The bias in measuring from a cross-cut perspective

This brings up an interesting debate when looking at the origin of this guideline. Having been created by the manufacturers of cross cut shredders themselves, the DIN guidelines primarily focus on the specifications that favor the shred dimensions obtained from cross cut shredding, namely slightly larger average particle size but with smaller individual differences between particles. This tailors the equipment to meet the strict tolerance requirements of DIN while not looking further into overall ability to reconstruct documents. In order to create a non-biased indication, other variables could be added.

Furthermore the shred size cannot be guaranteed when one or more of the cross-cut shredding ‘teeth’ have broken as paper can pass through without being shredded. When using a granulator shreds always need to pass a security screen, always guaranteeing a certain shred size

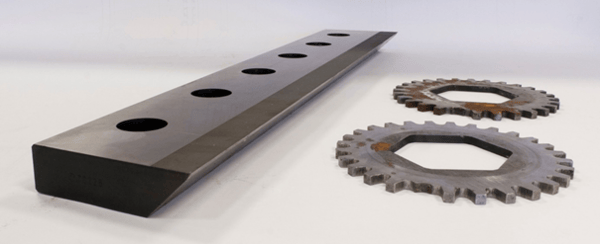

Picture of granulator knife (left) and cross cut knives (right)

Picture of granulator knife (left) and cross cut knives (right)

Ability to recover documents

The following question could then be posed: Is it harder to restore a 10 page document shredded into exact 5 square millimeter pieces or in shreds of which 95% ranges between 0.2 millimeter and 5mm millimeter pieces with 5% exceeding the 5mm mark? While the latter would not qualify for the same level of security as the former according to the DIN guidelines, a significant portion of particles would be impossible to restore due to their dust-like form. Additionally, when a large portion of shreds are significantly below the required shred size, shreds will be more homogenous and mix more easily, making them harder to restore.

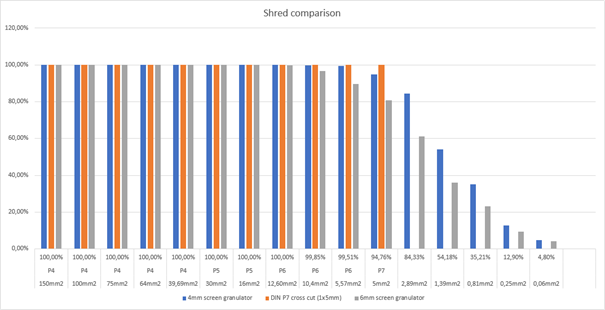

To present this difference, in the graph below we have included the percentage of shreds formed by a granulator and by a cross cut shredder that would pass the highest security level requirement for documents, DIN P7. As visible in the graph, the granulator does not manage to reduce 100% of the particles to the 5mm requirement, but manages to release over 80% of particles with a smaller shred size than 2,89 mm and still performs above 50% at little over 1mm. The cross cut shredder however is firmly limited in its 5mm range.

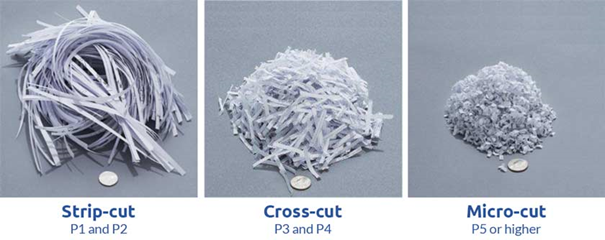

The moral of this comparison is that when approached purely from the perspective of complicating the recovery of documents, measuring only individual shred size limits the scope of solutions to the problem. Further security measures can be taken in the shred collection and processing methods. Central shred collection systems can mix the particles of thousands of shredded documents together while briquetting solutions can make potential recovery even more complex by compacting this mixed waste. To study the visual differences between shred particles, have a look at the images below.

Granulated (4mm screen)

Cross-cut

Are you looking for a solution to avoid reconstruction of secure documents and would you like to be advised in the different options that are available? Leave us a message with your question or request and we’ll gladly provide you with advice fit for your application.